Bullock, Logan & Associates, Inc. is a team of professional engineers with 180 years of combined experience in industrial cooling system design. With our services behind your industrial cooling and chilling systems, you can remain comfortable in knowing that all equipment is working optimally. Whether you need repairs, replacements, or design assistance for industrial cooling or chilling systems, we have what you need here at Bullock, Logan & Associates.

What Is Industrial Cooling?

The concept of industrial cooling is, at its simplest, like a home air conditioning system but on a much bigger scale. For many commercial and industrial buildings, such as hospitals, manufacturing facilities, restaurants, and more, having an efficient chilling system is an absolute necessity. This is where cooling systems like industrial chillers come in.

Types of Industrial Cooling & Chiller Systems

There are three main types of industrial cooling systems:

Air Chillers

Air chillers use ambient air to remove heat from a system or process. They are commonly used in applications where water availability or quality is limited, or where air cooling is preferred for specific reasons, such as avoiding water contamination or reducing water usage.

Water Chillers

Water chillers use water as the primary cooling medium. They are versatile and widely used in various industries for cooling processes and equipment. Water chillers can efficiently transfer heat and are often preferred for their reliability and effectiveness in maintaining consistent temperatures.

Evaporative Condensed Chillers

Evaporative condensed chillers use evaporation to cool the condenser coils, which in turn cool the refrigerant. These chillers are particularly effective in hot and dry climates, where evaporative cooling can significantly enhance efficiency and reduce energy consumption compared to traditional air or water-cooled systems.

Each of these types break down further into 4 subcategories:

Reciprocating

Reciprocating chillers are equipped with reciprocating compressors, which use a piston-driven mechanism to compress and cool the refrigerant. These chillers are often preferred for smaller-scale applications or where precise temperature control is required. They are relatively simple in design and offer good efficiency levels.

Centrifugal

Centrifugal chillers feature centrifugal compressors, which use rotating impellers to compress the refrigerant. These chillers are known for their high efficiency and capacity, making them suitable for large-scale industrial applications where significant cooling loads are required. They are often favored for their energy efficiency and reliability.

Screw Driven

Screw-driven chillers are equipped with screw compressors, which utilize rotating screw elements to compress the refrigerant. These chillers are well-suited for medium to large-scale applications and offer a good balance between efficiency, capacity, and reliability. They are often chosen for their ability to handle varying cooling loads efficiently.

Absorption

Absorption chillers utilize absorption technology to generate cooling by absorbing heat. These chillers are driven by heat rather than mechanical energy, making them suitable for applications where waste heat or low-grade heat sources are available. They are often used in combination with cogeneration systems or waste heat recovery to achieve energy savings and environmental benefits. Absorption chillers can be a sustainable cooling solution in certain contexts, particularly where renewable or waste heat sources are abundant.

The Best Industrial Cooling Solutions Near You

- A full engineering staff with 180+ years of collective experience

- $10 million in comprehensive insurance coverage

- Factory-trained crews dedicated solely to industrial cooling

- Access to patented state-of-the-art components that enhance performance, reducing industrial cooling system maintenance no matter the manufacturer

- Custom design assistance for industrial cooling systems, ensuring that clients receive tailored solutions optimized for efficiency, longevity, and performance

- Reputation founded on integrity, professionalism, and unwavering commitment to delivering high-quality workmanship

- Responsive customer support, ensuring timely resolution of inquiries, concerns, or emergencies

- Free inspections to provide valuable insights into the condition and performance of your systems

Don’t take a chance with an investment as important as your industrial cooling system.

Industrial Cooling & Chiller System Services We Offer

Regardless of what you need for your industrial cooling or chilling systems, we’ll determine which of our services will work best for your facility. You’ll be able to get everything required for an efficient and dependable system.

Evaluation of Industrial Cooling & Chiller Systems

Complete industrial cooling system evaluation including heat loads and sizing of piping valves and pumps. We will leave no part of your system overlooked upon inspection, ensuring that you have a system that gives you the best results. Our experts will inspect each part of your existing machinery to determine if there’s any inefficiency, with the ability to provide replacement cooling tower parts in addition to repairs and rebuilding services. Based on your needs, our design assistance can help you determine the exact specifications required for your equipment.

Our experts will ensure that your cooling or chilling systems operate the way they should for many years with the help of our dependable evaluation services.

Exclusive High-K Exchanger Pump Station for Industrial Cooling & Chiller Systems

Fully designed and self-contained pump station providing closed loop cooling and system cleanability without system shutdown. This can significantly help avoid breakdowns that might otherwise result in costly damages. You won’t need to worry about a malfunctioning system with a pump station that works for you. Like our other chilling system equipment, our pump stations are constructed using the best available materials to help them last for many years, preventing the need for frequent repairs or replacement parts.

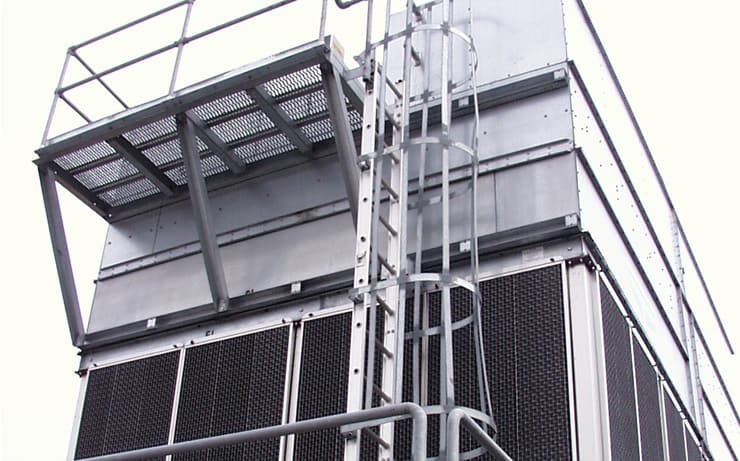

High Efficiency Heat Rejection for Industrial Cooling & Chiller Systems

Access to high efficiency Evapco evaporative cooling units to achieve the lowest possible energy consumption for your industrial cooling system. You’ll be able to benefit from more energy efficiency while saving money, enabling more profitability. Similar to our pump stations, Evapco coolers use the best materials to help ensure that facilities get the most out of their units. Customers won’t need to worry about frequent breakdowns or repairs. We’ll help you save money while expanding the longevity of your cooling and chilling systems.

Benefits of Our Industrial Cooling Systems & Solutions

Reliable Performance

With our systems, clients can count on consistent and reliable cooling performance to ensure the smooth operation of critical industrial processes.

Customized Solutions

We tailor our cooling systems to meet the specific needs and requirements of each client, ensuring optimal performance and efficiency for industrial processes.

Advanced Technology

Our systems incorporate cutting-edge technology and high-efficiency components to ensure that clients have access to the latest innovations in industrial cooling.

Improved Profitability

By optimizing cooling system performance and efficiency, our solutions contribute to increased profitability for our clients’ industrial operations.

Environmental Sustainability

By reducing energy consumption and emissions, our cooling solutions contribute to a greener and more sustainable industrial operation.

Long-Term Cost Savings

Our cooling solutions are designed for longevity, reducing the need for frequent repairs and replacements and ultimately saving money over time.

Expert Support

Clients benefit from the expertise of our team of experienced engineers, who provide comprehensive support throughout the installation, maintenance, and operation of the cooling systems.

Responsive Customer Service

We offer quick and responsive customer support to address any issues or concerns promptly, minimize downtime, and maximizing productivity.

Get Started with Efficient Industrial Cooling Systems & Solutions

In addition to many other services, we offer custom design assistance for industrial cooling systems. Regardless of the extent of your specific project, we’re ready to give you the help you need. We’ll give you everything you need to help ensure that your cooling equipment lasts for many years, with minimal risk of breakdowns, while providing the highest level of achievable efficiency.

For help with industrial cooling system design assistance today, contact us at any time. We’re ready to provide the assistance you need regarding cooler and chiller design and installation, with the expertise needed to complete installation with maximum efficiency. You’ll benefit from a complete system that gives you the best achievable results. We can also provide assistance with heat exchangers.

Contact Us